inclined coil spring finger·CUSTOMIZATION

The canted coil spring is also called spring contact finger, contact finger spring, and ring spring. It can transmit strong current in a small space and can also be used as a pure mechanical connection. There are no restrictions on its use, and it is suitable for use in a variety of static or dynamic medium and high pressure environments. The size of the spring contact finger and the number of independent coil turns make the spring suitable for various electrical contact designs, and the largest contact point is the best current-carrying capacity for electrical or EMI shielding. Each coil will independently compensate for contact and surface changes, which allows for wider tolerances between accessories. Multiple contact points increase conductivity, and its operating temperature is relatively low, so the service life is longer.

Our spring finger technology is used for power contacts in various industries, including medical electronics, medical equipment, aerospace and defense, energy and automobiles, etc.

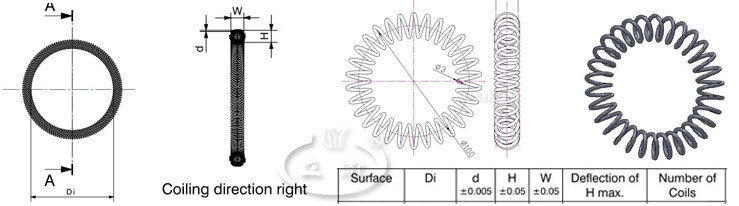

Technical parameters of finger spring (also known as canted coil spring, ring spring)

| To customize the finger spring, you need to provide the following necessary parameter information: | |||

|---|---|---|---|

| Wire diameter d: mm | (Note: the diameter of the spring wire) |

|

|

| Spring inner diameter Di: mm | (Note: inner diameter of ring spring) | ||

| Oblique circle major diameter W: mm | (Note: oblique circle ellipse major axis) | ||

| Oblique circle diameter H: mm | (Note: Oblique circle ellipse minor axis) | ||

| To customize the finger spring, you also need to provide the following technical requirements: | |||

| Total number of laps: | (Note: the total number of turns of the oblique coil) | ||

| Material requirements: | (Such as: beryllium copper C17200, C17500, chromium zirconium copper C18500, stainless steel SUS304, 316... etc.) | ||

| Surface treatment: | (Description: copper plating\nickel plating\silver plating\gold plating\...etc) | ||

| Outer diameter of spring: | (Note: the outer diameter of the ring spring) | ||

| other request: | (Such as: spring usage, current requirements, shape and flatness requirements, welding requirements, etc.) | ||

|

|||

中文站

中文站